TEI, the flagship of the Turkish aviation engine industry, shared the technical roadmap of national projects that will mark 2026 at a strategy conference held in Antalya. TEI General Manager Prof. Dr. Mahmut Faruk Akşit announced that they have reached the Critical Design Review (CDR) phase, one of the most vital turning points in the engineering cycle, for the indigenous engine of the National Combat Aircraft KAAN. This development indicates that the conceptual design of the engine is complete and that it has entered the final technical review phase before production. Meanwhile, the serial production delivery date for the TS1400, the heart of the GÖKBEY, has been confirmed as 2026.

The Defence and Aviation Industry Global Strategies Conference, held in Antalya under the coordination of the Presidency of Defence Industries, witnessed the technical details of Turkey's march towards independence in engine technologies. Speaking at the meeting, TEI General Manager Prof. Dr. Mahmut Faruk Akşit shared critical technical data with the public, ranging from the KAAN engine project, about which they had been discreet until now, to UAV engines specialised for the naval forces.

Critical Process for the Heart of KAAN: CDR Phase Reached

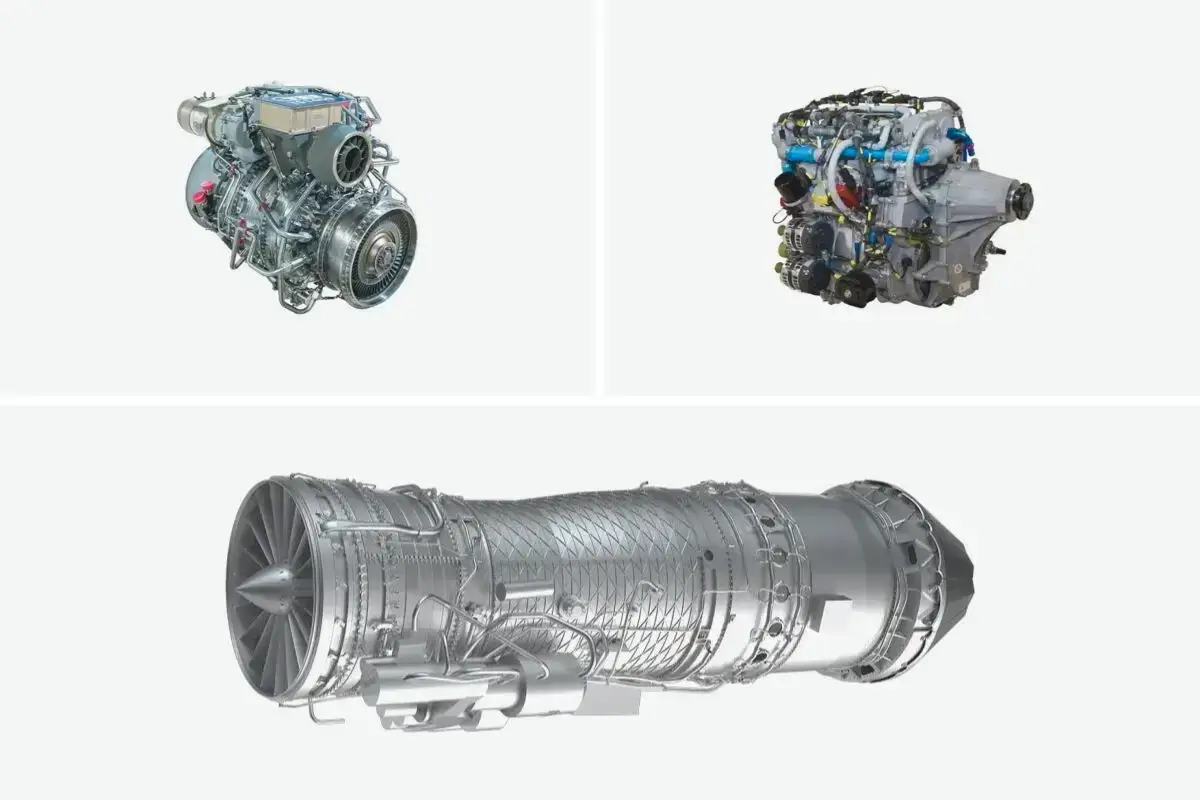

The most strategic detail in Prof. Dr. Akşit's presentation concerned KAAN's indigenous power unit (the main engine within the TF35000/TF10000 roadmap). Akşit announced that the PDR (Preliminary Design Review) processes for the engine project have been completed and that they have now reached the CDR (Critical Design Review) phase.

What Does Reaching the CDR Phase Mean?

In aerospace engineering, reaching the CDR phase indicates that the engine's design has matured and is ready for its final and most challenging paper-based examination. During this phase, every component of the engine, its thermodynamic data, and material strengths are scrutinised down to the finest detail for the last time. When the CDR process is successfully completed (when the CDR is said to be "closed"), the design is frozen, and the command is given to the machinery to begin manufacturing the first prototype. TEI's announcement signals that the final stretch on the path to prototype production for KAAN's indigenous engine has been reached.

TS1400 Turboshaft Engine: Serial Production Delivery This Year

The long-awaited schedule for Turkey's first national helicopter engine, the TEI-TS1400, was also announced. For the engine, which had previously powered the GÖKBEY helicopter with prototype engines and surpassed its counterparts by reaching 1740 horsepower during tests, 2025 was a year of certification and supply chain finalisation.

Highlighting the difficulty of producing an engine that will power a manned aircraft to civil aviation standards, Akşit stated that the certification processes for subcontractors were completed throughout 2025. It was announced that the first serial production TS1400 engines, assembled entirely with certified parts, will be delivered to TUSAŞ within 2026 following ground tests. This move signifies the complete nationalisation of the GÖKBEY, not only with its airframe but also with its engine.

The Altitude and Saltwater Challenge in UAV Engines

TEI has proven with technical data that it has risen to a standard-setting position globally in the UAV engines segment.

World Altitude Record with the PD170:

The TEI-PD170, developed for MALE-class UAVs, challenges altitude loss thanks to its twin-turbocharger technology. Akşit announced that the engine exceeded the targeted 40,000 feet altitude, reaching 42,000 feet (approximately 13 km), and set a world record in this class.

The Marinised PD200 for the TB3:

It was revealed that the TEI-PD200 engine, specially developed for TCG Anadolu and the Bayraktar TB3, is not merely a power upgrade but a completely overhauled naval engine.

- 100+ Parts Modified: In the engine developed based on the PD170, over 100 parts and the gearbox were modified for resistance to corrosion and maritime conditions.

- Saltwater Test: The PD200 was subjected to salt chamber tests, one of the most challenging phases of military specifications (Mil-Spec). Successfully passing intense salt fog tests lasting up to 100 hours, the engine proved it can operate without corrosion during missions over the sea.

A Vision for Becoming a Game-Changer in Engine Technology

Prof. Dr. Mahmut Faruk Akşit's statements indicate that TEI's vision for 2026 is not merely to manufacture but to develop certified and exportable technologies. Reaching the CDR phase for KAAN's engine and transitioning to serial production deliveries for GÖKBEY's engine signals that Turkey is ending its foreign dependency on critical systems in aviation engines.

Reply