TRMOTOR, the developer of engine and power systems for the National Combat Aircraft KAAN, has clarified the current roadmap for the project. While the company continues the design and subsystem development for the aircraft's main engine, the TF35000, it has reached the final stages for the indigenous Auxiliary Power Unit (APU) systems. According to information published in TUSAŞ's media organ Gökvatan, Türkiye's first indigenous APU system, "APU-60," will be integrated into KAAN within 2026.

Operating as Türkiye's design center in the field of aviation engines, TRMOTOR is conducting simultaneous operations on the systems (TF35000 and APU) that will meet the thrust and energy requirements of the KAAN project. Accelerating main engine efforts via the consortium established with TEI in 2024, the company has passed a significant milestone in nationalizing the critical subsystems that provide the aircraft's ground energy needs and engine starting functions. 2026 will be a critical year where indigenous power units meet the platform.

TF35000 and Holistic Subsystem Design

KAAN’ın gökyüzündeki hakimiyetini sağlayacak olan 35.000 libre itki sınıfındaki milli motor TF35000’in geliştirilmesi sürecinde TRMOTOR, kritik bir rol üstleniyor. 2022 yılında KAAN’ın ana motorunun kavramsal tasarım kontratını imzalayan ve 2024 yılında TEI ile kurulan konsorsiyumla güç birliğine giden şirket, motoru sadece bir makine olarak değil, bir sistemler bütünü olarak ele alıyor.

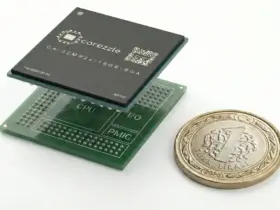

TRMOTOR’s responsibility on the TF35000 extends from the engine core to peripheral units. The company carries out the design and development of vital subsystems such as the FADEC (Full Authority Digital Engine Control), lubrication, fuel, ignition, actuation, pneumatic systems, and the gearbox. This holistic engineering approach ensures the engine performs reliably under demanding combat conditions.

APU and ATS: Independence on the Ground

Bir savaş uçağının ana motorlarını yerde, harici bir kaynağa ihtiyaç duymadan çalıştırabilmesi operasyonel esneklik için hayati önem taşır. İşte bu noktada devreye APU (Auxiliary Power Unit – Yardımcı Güç Ünitesi) ve ATS (Air Turbine Starter – Hava Türbinli Başlatıcı) giriyor.

TRMOTOR is realizing a first in Türkiye with these systems developed for KAAN:

- Operational Principle: The APU is a smaller gas turbine engine compared to the main engine. It activates before the main engines to power the aircraft's avionics, air conditioning, and electronic systems. The pressurized air produced by the APU is transferred to the ATS system; the ATS uses this air to rotate the turbine inside, turning the main engine's shaft to provide the initial start.

- Strategic Value: This system eliminates KAAN's dependency on ground support equipment, enabling operations from any base or civilian airfield.

2026 Target: APU-60 Integration

TRMOTOR’un yürüttüğü en somut projelerden biri, Türkiye’nin ilk kez yerli ve milli imkanlarla geliştirdiği APU-60 sistemi. KAAN projesi için özel olarak tasarlanan bu güç ünitesinin, 2026 yılı içerisinde uçağa ilk entegrasyonunun yapılması planlanıyor.

As test phases continue without interruption, the activation of the APU-60 will provide KAAN with a fully indigenous solution for engine starting and ground power requirements.

Commercial Solution: APU-40

TRMOTOR, askeri projelerden edindiği know-how’ı ticari alana da taşıyor. Şirket, APU-60’ın yanında daha kompakt yapıda yeni bir yardımcı güç ünitesi olan APU-40 üzerinde çalışıyor.

- Core Integration: While core engine integration studies for the APU-40 project are ongoing, test activities are targeted to begin in the first quarter of 2026.

- Scope: This model is intended to be integrated into commercial aircraft and rotary-wing (helicopter) platforms, aiming to become a high-export-potential product.

National Test Infrastructure

Validating and certifying an engine is as critical as designing it. TRMOTOR has established a vast test ecosystem through university-industry cooperation.

- Gebze Technical University: The "Altitude Systems Center of Excellence" established here simulates how engines behave under high-altitude conditions.

- METU (ODTÜ): Aerodynamic and thermal tests of engine parts are conducted in the combustion and flow laboratories within the Middle East Technical University.

Across Ankara, Eskişehir, and Kocaeli, TRMOTOR conducts verification activities ranging from compressor tests to combustion chamber tests, and from APU assembly to gearbox activation.

Indigenous Engine is a Matter of Survival

TRMOTOR Genel Müdürü Prof. Dr. Osman Saim Dinç, yürütülen çalışmaların sadece mühendislik başarısı olarak görülmemesi gerektiğini vurguluyor. Motor teknolojilerini bağımsızlık, sürdürülebilirlik ve tedarik güvenliğinin kesişim noktası olarak tanımlayan Dinç, şu değerlendirmede bulunuyor:

"We evaluate indigenous engine studies with a focus on the issue of national survival (beka). This situation makes the strategic importance of establishing our own capability in propulsion and power systems even more visible. With these projects, a capability acquisition that will create a catalytic effect on Türkiye's indigenous aviation engine technologies will also be realized."

In line with KAAN’s goal of flying with a Turkish-made engine in 2028, TRMOTOR’s APU integration and sub-system tests planned for 2026 represent one of the project’s most critical milestones.

Reply