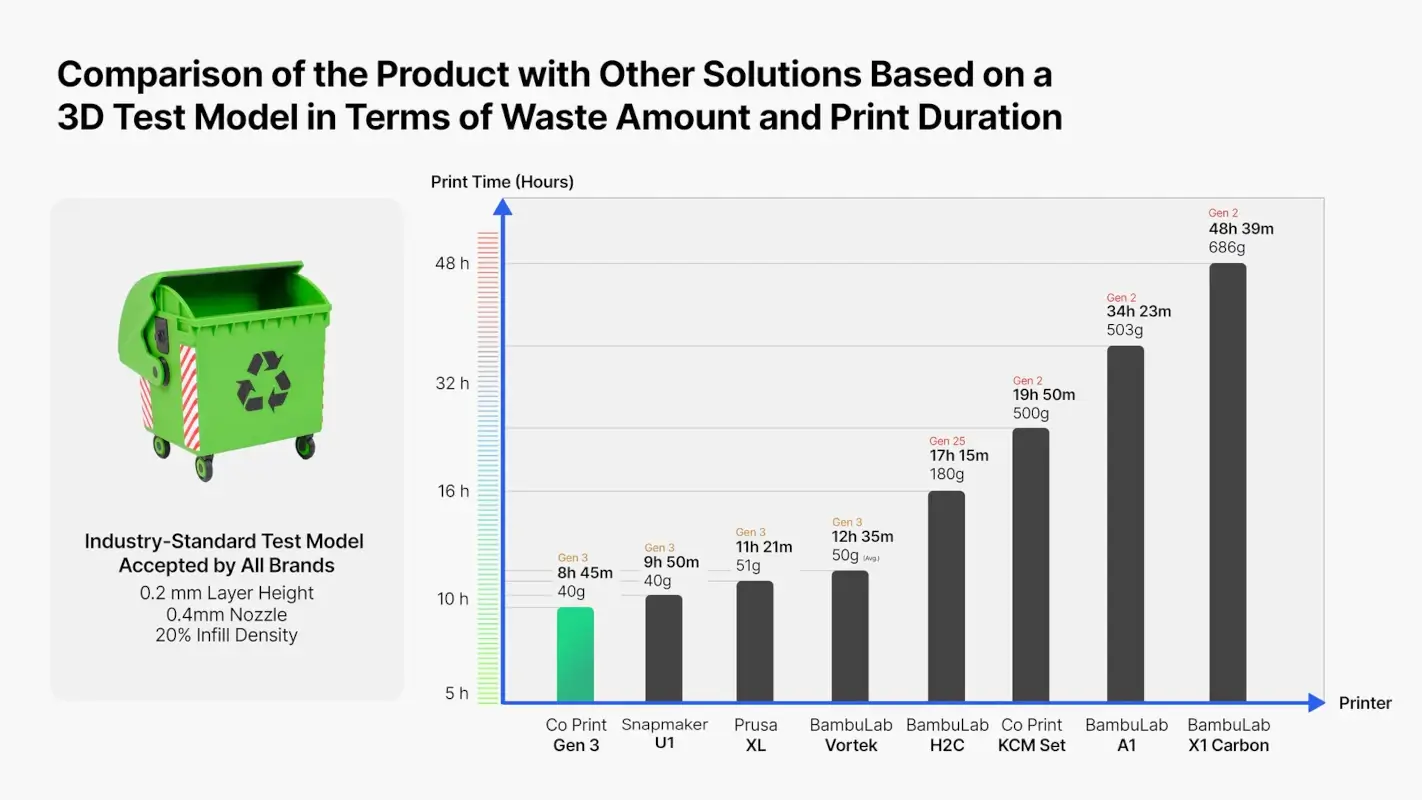

Co Print, a company operating in the field of 3D printing technologies, showcased its revolutionary solution developed in opposition to the "multi-color but high-waste" systems that dominate the industry. The company's new flagship product, which it describes as the "Era of 3rd Generation Printing," was unveiled. Co Print Quadro, Co Print is more than just a printer; it's an engineering marvel that brings industrial multi-material capabilities to the desktop. Having shed its identity as a module manufacturer, Co Print has risen to the level of an original equipment manufacturer (OEM)., IQEX (Independent Quad Extrusion) It challenges its global competitors with its technology.

Preparing to launch globally via Kickstarter Co Print Quadro, It promises a waste-free solution, especially for professional users and makers who are plagued by "purge tower" and "filament poop" problems.

IQEX Technology and Kinematic Structure

The key difference that sets Co Print Quadro apart from other “color” printers on the market lies in its printhead design. Taking standard IDEX (Independent Dual Extruder) systems a step further, 4 independent toolheads moving on a single axis owner.

This architecture (IQEX) offers the following technical advantages:

- Zero Cross-Contamination: Because each color or material exits its own hotend, the risks of color mixing or nozzle clogging experienced in single-nozzle systems (such as Bambu Lab AMS or Prusa MMU) are eliminated.

- Waste-Free Transition: Since the nozzle doesn't need to be cleaned during color change, there's no need to print a "purge block." This shortens printing time and prevents valuable filament from being wasted.

- Multi-Material Capability: It offers not only color, but also the possibility of using PLA and PETG, TPU and rigid plastics, or water-soluble support materials simultaneously.

For Speed Enthusiasts: 20,000 mm/s² Acceleration

Quadro is not just a multi-head system, but also a high-speed "speed benchy" beast. The device's kinematic data is quite impressive:

- Printing Speed: 600 mm/s (Maximum).

- Acceleration: 20,000 mm/s².

This acceleration value allows the print head to move without losing speed during directional changes (especially corner turns and infill scans). To stabilize this performance, the chassis... “Rigid Frame Structure” A rigid frame structure has been chosen. The fuselage; aluminum extrusion profiles, hardened steel (hardened steel) components and injection molded It consists of a hybrid combination of components. This structure is critical for minimizing the "ringing" effect (vibration rings) that occurs at high speeds.

Hardware Ecosystem and Smart Features

The device's specifications include all the "Life Quality" features expected from a modern 3D printer.

- Large Print Volume: 300x300x300 mm. (Piyasa standardı olan 256mm küp hacimlerden yaklaşık %60 daha fazla hacim sunuyor, bu da büyük kasklar veya cosplay parçaları için tek parça baskı imkanı demek).

- Automatic XYZ Calibration: By performing automatic calibration not only on the Z-axis (Z-offset) but on all axes, it eliminates first-layer adhesion problems.

- AI-Powered Camera: An AI-powered camera system is built-in that detects "spaghetti" errors that may occur during printing and stops the printing process.

- Limit Detection: An advanced limit detection system that detects axis boundaries physically or without sensors (sensorless homing).

User Experience and Interface

The complexity of the technology is simplified by a user-friendly interface. The device features a large touchscreen that allows for easy filament loading (load/unload), temperature controls, and cooling fan settings. This "User Friendly Interface" visually monitors which material (PLA, PETG, etc.) is loaded in which printhead (Tool 1, Tool 2, etc.).

Co Print Original R&D Project

Co Print Quadro is not a "assembly industry" product, but an original R&D project. Its entry into the "multicolor printing" market, currently dominated by Bambu Lab's AMS system, by offering the Prusa XL's "toolchanger" concept in a much more compact and accessible format (IQEX), is a strategic move. In particular... waste-free This emphasis could make Quadro the number one choice for commercial printing farms that are concerned about filament costs. As yuzde100yerli.com, we support the goal of Turkish engineering: “True multi-color printing without complex workflows.”.

Take advantage of the limited-time Co Print Quadro pre-order discount and be among the first to experience this new product of Turkish engineering: multi-color, low-waste 3D printing technology. https://coprint3d.com You can visit this address.

Reply