Türkiye's defense industry has gained significant momentum in recent years. The flagship projects developed across land, air, and sea platforms have become the most concrete indicators of the country's vision for independence and its current level of development. However, a common fate for these projects has been problems with engine supply. While the ALTAY main battle tank, the KAAN national combat aircraft, and the TF-2000 air defense destroyer represent Türkiye's engineering prowess, dependence on foreign engine suppliers continues to hinder the progress of these projects.

ALTAY and BATU Engines: The Battle at the Heart of Land Power

The story of the ALTAY tank stands as one of the most striking examples of engine dependency. The project, which began in 2007, aimed to create Türkiye's first national main battle tank. However, the plan was to source the engine and transmission from Germany. Political tensions and export restrictions stalled this process, delaying the project for years. As a solution, the Doosan engine and S&T Dynamics transmission from South Korea were brought in. This power pack will be used in the first mass-produced ALTAY tanks.

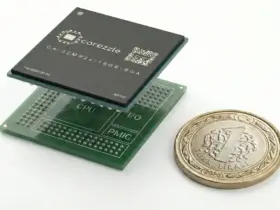

The main goal is the introduction of the 1500 horsepower BATU engine and domestically produced transmission developed by BMC Power. The BATU engine had its first firing in 2021, tests are ongoing, and it is expected that the fully domestically produced power pack will be used in ALTAY tanks after 2028. This process will constitute a critical turning point in Türkiye's transition to engine independence in its land forces. With the introduction of the BATU engine, Turkey will have access to the latest engine technology necessary for its land forces, and we believe that the diversity of land vehicles will accelerate from this point onwards.

KAAN and the Engine Problem: The Toughest Test for a Fifth-Generation Aircraft

A similar situation arises in aviation. KAAN, as Türkiye's fifth-generation fighter jet, holds great strategic value. However, serious engine problems are being experienced in the KAAN project, just as in the ALTAY tank project. The prototypes use US-made General Electric F110 engines. According to Foreign Minister Hakan Fidan, the necessary licenses for KAAN's engines are pending in the US Congress, and this is disrupting the production schedule.

It is important to emphasize that the delay mentioned by Mr. Hakan Fidan does not include the KAAN prototypes currently in production or scheduled for production. The necessary engines for the 6 KAAN prototypes to be produced by TUSAŞ have already been procured, and therefore no delays are expected in the prototype production process. The delay referred to here most likely stems from TEI's inability to begin production of F110 engines, despite having the capability, because it does not possess a US license.

In response to this problem, Türkiye accelerated its own turbofan projects (TF10000 and TF35000). A crucial distinction needs to be made here: The TF10000 engine was not developed specifically for KAAN. Developed by TEI, this engine is Türkiye's first afterburner turbofan engine, providing a technological advantage and particularly Unmanned combat aircraft like KIZILELMA It offers a suitable power pack. The main target engine for KAAN is... TF35000 with 35,000 pounds of thrust.. This engine will be KAAN's permanent solution and is planned to be commissioned in the 2030s.

Although technology transfer talks with Rolls-Royce are ongoing, Turkey aims to guarantee its independence by establishing its own ecosystem through TEI and TRMotor. The export of 48 KAAN aircraft to Indonesia is planned to be powered by domestically produced engines. This ambitious goal could be one of the most concrete indicators of Türkiye's engine independence in the long term. With the completion of the TF35000 engine, Turkey will possess one of the highest-level engines available in the military aviation sector. From this point on, we believe that air platforms will not be limited to KAAN but will rapidly diversify.

TF-2000 and MUGEM: Are There Engine Risks at Sea?

Two major Turkish projects stand out in the maritime sector: TF-2000 air defense destroyer And MUGEM (National Aircraft Carrier).

The TF-2000, with its 8300-ton displacement, ÇAFRAD AESA radars, and SİPER missiles, will enhance Türkiye's deterrence capabilities at sea. However, engine requirements are a critical issue here as well. Gas turbine and diesel combinations are planned for the ships. Dependence on US-made LM2500 gas turbines shows that engine crises experienced on land and in the air could also occur in naval projects.

MUGEM represents Türkiye's "floating fortress" vision. The ship, which will be 285 meters long and have a displacement of 60,000 tons, will be able to carry up to 50 manned and unmanned aerial vehicles. TUSAŞ's HÜRJET naval version, ANKA-3, and Baykar's KIZILELMA will be able to take off from this platform. MUGEM's propulsion system is also based on four LM2500 gas turbines in a COGAG configuration. This shows that engine dependency poses a strategic risk even on an aircraft carrier scale. Although there is no immediate risk of obstruction on the horizon, Turkey is accelerating its localization efforts in marine engines as well.

Global Perspective: The Purpose of Embargoes

In fact, using systems sourced from different countries when developing a tank, aircraft, or ship is commonplace worldwide. Countries like the US, Germany, France, and South Korea also utilize foreign engines, radars, or electronic systems in major defense projects.. This is a natural part of the global defense industry ecosystem.

However, the engine embargoes that Türkiye is facing are outside this norm. The issue here is not technical, but political. The UAVs, armed drones, armored vehicles, and air defense systems that Türkiye has developed in recent years are in high demand from friendly and allied countries. This success has become a source of discomfort for some actors in the current world order. Therefore, the obstacles placed in the way of engine supply should actually be interpreted as strategic moves aimed at slowing down Türkiye's rise.

The Motor Vehicle Barrier Will Be Overcome Through Domestic Production.

The ALTAY BATU engine, the KAAN engine problem, the TF-2000 destroyer, and the MUGEM engine needs represent some of the biggest strategic challenges Türkiye has faced in its defense industry. However, these crises have also become a source of motivation for Turkish engineers. TEI's PD170, TS1400, and TF6000 projects, BMC Power's BATU, UTKU, and AZRA engines, and ASELSAN's electric motors form the building blocks of this journey towards independence.

Motor vehicle obstacles, instead of breaking Türkiye's resolve, have strengthened it. Because now Turkish engineers are producing not only vehicles, but also the heart of those vehicles. And when these hearts one day begin to beat entirely domestically and nationally, Türkiye's defense industry will be freed from its chains.

Key words: ALTAY BATU engine, KAAN engine problem, TF-2000 destroyer engine requirement, MUGEM engine, National Aircraft Carrier, domestic engine projects, Turkish defense industry, engine embargo, BMC Power BATU, TEI TF35000, TF10000 KIZILELMA, national engine independence

Reply